Coolnomix®

Coolnomix® is an energy saving device that guarantees to reduce kWh consumption when installed on AC or refrigeration equipment by between 20% and 40%.

Our globally patented, innovative, retrofit technology is actively reducing kWh consumption across hotel chains, restaurant groups, Universities, the NHS and some of the leading companies in the UK. By reducing kWh consumption on a daily basis, Coolnomix® is helping organisations that rely on their AC & refrigeration equipment to fight back against the rising costs of electricity!

As well as being completely maintenance-free, Coolnomix® is saving our clients up to 40% in cooling mode and up to 20% in it’s new heating mode.

Coolnomix® can save up to 40% of the energy consumption on all types of air-conditioning units. Installed across all commercial settings, Coolnomix® could save 6.9 TWh in Europe alone.

Coolnomix® can help any business who uses air conditioning to cool environments or refrigeration to keep produce chilled. We have installed Coolnomix® in many different businesses:

Don’t just take our word for it…

Sodexo

Frazer Russell | Global Energy Manager

”I am very impressed with the Coolnomix technology with its proven performance to deliver energy and cost saving across our clients air conditioning and refrigeration estates. Coolnomix has surpassed my expectations and we are actively endorsing it across our client base!

Critically important to Sodexo, the Coolnomix technology does not affect either the operating performance or impact on the manufacturers warranties whilst continuing to deliver valuable energy savings.”

NHS England

Tom Stewart |Net Zero Carbon Technical Innovations Manager

‘I’m sold on Coolnomix, I need no further convincing!‘

Lloyds Banking Group

Matteo Deidda | Senior Sustainability Manager at Lloyds Banking Group

” We are very excited to work with the finalists (Coolnomix) and our partners in the coming months to pilot their technologies in our offices and branches. The winning technology will have access to our innovation budget to test their solutions in our buildings, and roll out at scale if the pilots are successful. This is a great opportunity for speeding up our transition towards a greener future and achieve the Group’s operational climate pledges.”

Technical Specifications

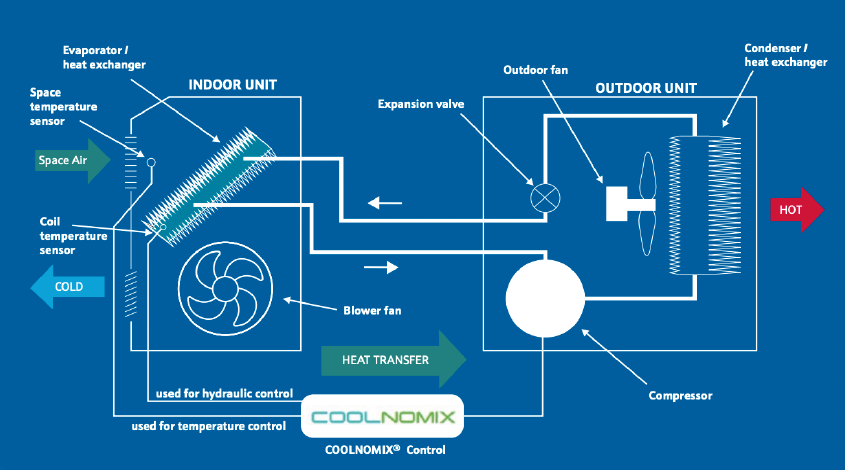

In most air-conditioning applications, a lot of energy is wasted because the unit’s compressor (the primary running cost component) runs much longer than necessary. Our patented Optimised Refrigerant Supply® (ORS®) process, integrated into the advanced Coolnomix® control device, reduces the cooling system compressor’s run-time, thus reducing electricity consumption, even in the most demanding, high and humid environments.

The Coolnomix® ORS® technology uses two temperature sensors in analgorithmic energy trading control arrangement to monitor the thermodynamic (room or space temperature) and the hydraulic (refrigerant supply) performance of the connected air-conditioning or refrigeration system.

In operation, this algorithmic energy trading approach first uses the room or space temperature sensor to ensure that a required setpoint has been achieved. Subsequently, this temperature sensor ensures that the space is maintained within +/-0.5°C (+/-0.9°F) of the required setpoint.

Meanwhile, a second temperature sensor connected to the indoor evaporator coil is used to identify when the compressor has done its useful hydraulic work in producing a supply of high-pressure liquid refrigerant. Using the built-in algorithmic energy trading control, the Coolnomix® ORS® advanced system then starts and stops the compressor at appropriate times to optimise running costs.

Net zero is coming…

“Growing demand for air-conditioners is one of the most critical blind spots in today’s energy debate. If left unchecked, energy demand from air-conditioners will more than triple by 2050. The answer lies first and foremost in improving the efficiency of air-conditioners, which can quickly slow down the growth in cooling-related electricity demand. Indeed, the opportunity for efficient cooling lies in the market’s current inefficiencies: there are huge disparities in the efficiencies of air-conditioners sold today across the globe. ” – Fatih Birol, Executive Director, IEA

Applications